Technical Information

Material specifications and recyclability guidelines for components used in the Tag Talka product range.

Paper Graphic

There is no need for harmful

foamed PVC or easily damaged

card promotions. This

graphic holder effectively

displays, and protects low-cost paper

graphics, which can be

quickly and easily updated.

Graphic holders come in a

diverse selection of shapes,

sizes, and colors, allowing

for customization to fit the

unique branding and store

environment.

Plastic Spindle

The rigid plastic spindle enables the graphic holder to rise smoothly with minimal resistance when bumped, reducing product disruption. Its self-leveling function is ideal for cascade fixtures, ensuring consistent alignment and presentation. Engineered for high-traffic environments, it offers reliable movement and resilience without compromising the display’s intended position or visibility.

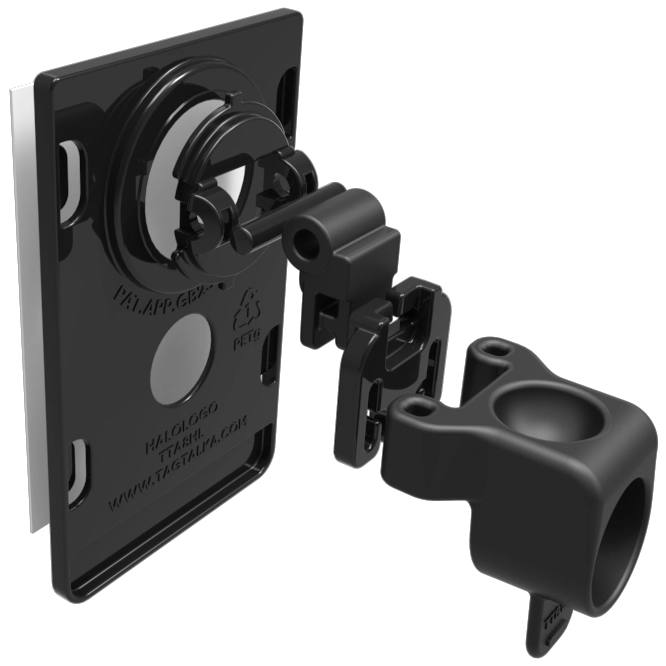

Gimble Plate

The injection-moulded gimble plate enables smooth, controlled rotation for optimal product positioning. Integrated detent limit stops prevent accidental over-rotation or inversion during use. Designed for durability and precision, it ensures consistent alignment and functionality, even in high-traffic retail settings where display integrity and long-term reliability are critical.

Rubber Body

The flexible rubber body is engineered to stretch and securely fit 95% of standard in-store rail arms. Custom bodies are available for compatibility with nearly any rail profile, from narrow wire to large round tubes. Designed for demanding retail conditions, it offers exceptional durability, tear resistance, and long-term performance without losing grip or shape over time.

Rubber Head

The low-resistance rubber head allows multidirectional flex, enabling the graphic holder to bend safely when contacted by shoppers. This flexibility helps prevent damage to displays while maintaining visual integrity. Ideal for dynamic retail spaces, it enhances durability and customer interaction without compromising the display’s form, stability, or functionality.

Plastic Neck

The rigid plastic neck separates the rubber head from the rubber body, ensuring that any movement or flex at the head does not disturb the holder’s fixed position on the rail arm. This isolation preserves display alignment and prevents slippage, even under repeated contact in high-traffic retail environments.

Graphic Holder

This injection-moulded graphic holder is designed to self-level on two axes, maintaining visibility across various viewing angles. Its flexible yet durable build absorbs impacts and endures the demands of high-traffic retail environments. Ideal for stores requiring long-lasting, low-maintenance display components.

Technical Information

- Tag Talka products are engineered for strength, flexibility, and durability to perform reliably in demanding retail environments. Through precision injection molding and fabrication, we ensure components feature smooth edges and rounded corners, prioritizing safety for both retail staff and customers.

- We fully understand the challenges posed by busy, high-traffic settings and design accordingly. Each product undergoes rigorous testing to verify functionality, safety, strength, and flexibility. We carefully select materials that resist cracking, splitting, and warping, ensuring consistent performance throughout their in-store lifecycle.

- Manufacturing processes emphasize impact resistance to maximize product longevity, reducing the need for frequent replacements. Below is a list of key materials that we employ in our products. We don’t use them all in each product but prioritize materials depending on what a customer requires.

- We focus on performance and recyclability, but also use materials recognized as ‘in-demand’ by recycling facilities—guaranteeing responsible end-of-life recycling and contributing to sustainability.

Material list

The items below show some of the main materials used in the manfacturing of Tag Talka products. Each material is recyclable or biodegradeable, with some being in high demand for recycling purposes.

PET

Polyethylene Terephthalate

Recyclability

In demand

Flexibility

Strength

Density: 1.33–1.38 g/cm³ | Tensile: 50–80 MPa

Flexural: 2000–3000 MPa | Elongation: 30–150%

Impact: 20–50 J/m | Hardness: R95–R120

Skin

Food

Allergy

PET-E

Enhanced Polyethylene Terephthalate

Recyclability

In demand

Flexibility

Strength

Density: ~1.35 g/cm³ | Tensile: 55–75 MPa

Flexural: ~2200 MPa | Elongation: 80–100%

Impact: ~30 J/m | Hardness: R100–R115

Skin

Food

Allergy

PETg

Polyethylene Terephthalate Glycol-Modified

Recyclability

In demand

Flexibility

Strength

Density: ~1.27 g/cm³ | Tensile: 50–65 MPa

Flexural: ~2000 MPa | Elongation: 120–150%

Impact: ~40 J/m | Hardness: R80–R100

Skin

Food

Allergy

SAN

Styrene Acrylonitrile

Recyclability

In demand

Flexibility

Strength

Density: ~1.08 g/cm³ | Tensile: ~60 MPa

Flexural: ~2500 MPa | Elongation: ~3%

Impact: ~25 J/m | Hardness: R110–R120

Skin

Food

Allergy

PP

Polypropylene

Recyclability

In demand

Flexibility

Strength

Density: 0.90–0.91 g/cm³ | Tensile: 30–40 MPa

Flexural: 1300–1800 MPa | Elongation: 200–700%

Impact: ~35 J/m | Hardness: R80–R100

Skin

Food

Allergy

HIPS

High Impact Polystyrene

Recyclability

In demand

Flexibility

Strength

Density: 1.03–1.06 g/cm³ | Tensile: ~35 MPa

Flexural: ~2000 MPa | Elongation: ~50%

Impact: ~30 J/m | Hardness: R95–R105

Skin

Food

Allergy

TPE

Thermoplastic Elastomer

Recyclability

In demand

Flexibility

Strength

Density: 0.89–1.26 g/cm³ | Tensile: 5–30 MPa

Flexural: 100–800 MPa | Elongation: 300–600%

Impact: ~25 J/m | Hardness: Shore A 20–90

Skin

Food

Allergy

Silicone Rubber

Clear / White / Black Silicone Rubber

Recyclability

In demand

Flexibility

Strength

Density: 1.1–1.3 g/cm³ | Tensile: 5–12 MPa

Elongation: 200–700% | Hardness: Shore A 20–80

Impact: ~20 J/m | Hardness: R85–R100

Skin

Food

Allergy

PLA

Polylactic Acid (Biodegradable)

Recyclability

In demand

Flexibility

Strength

Density: 1.24–1.26 g/cm³ | Flexural: 3000–5000 MPa

Elongation: 2–10% | Hardness: R105–R115

Impact: ~15 J/m | Hardness: R100–R110

Skin

Food

Allergy

rPET

Recycled Polyethylene Terephthalate

Recyclability

In demand

Flexibility

Strength

Density: 1.30–1.38 g/cm³ | Tensile: 50–75 MPa

Flexural: 2200–3000 MPa | Elongation: 30–150%

Impact: 25–55 J/m | Hardness: R95–R115

Skin

Food

Allergy